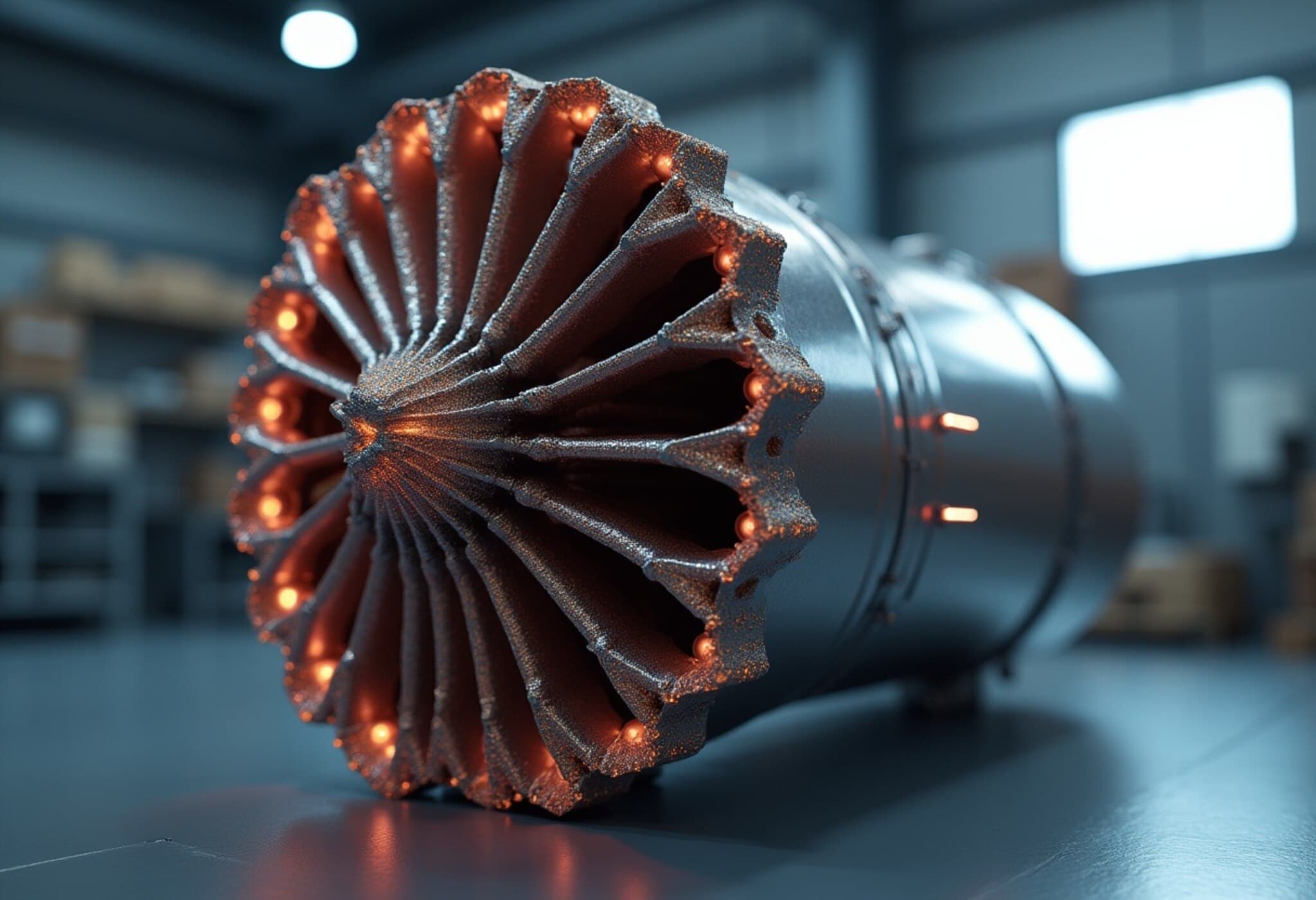

India’s Agnikul Cosmos Innovates with Largest Single-Piece 3D-Printed Rocket Engine

In a groundbreaking leap for aerospace technology, Indian startup Agnikul Cosmos has successfully developed the world’s largest rocket engine printed entirely as a single piece using Inconel, a high-strength, heat-resistant superalloy. This pioneering achievement not only showcases India’s rapid ascent in the global space race but also marks a significant milestone in additive manufacturing for rocketry.

The Technology Behind the Innovation

The newly engineered rocket engine stretches about a meter in length and is produced as one integrated component — devoid of any welds, bolts, or joints from the fuel inlet to the plume exit. This design innovation dramatically simplifies the manufacturing process, reducing production complexity and potential failure points that usually arise from multi-part assemblies.

Inconel, known for its exceptional performance under extreme temperature and pressure, makes this engine uniquely suited to withstand the brutal conditions of spaceflight. By applying advanced 3D printing techniques, Agnikul has not only achieved unprecedented scale for a single-piece printed engine but also optimized it for fluid dynamics and structural resilience.

Why This Matters: Efficiency, Cost, and Performance

- Production reduction: The integrated 3D printing approach slashes manufacturing time by over 60%, accelerating development cycles.

- Weight and complexity: Eliminating joints reduces engine weight and mitigates the risk of mechanical failures.

- Cost-effectiveness: Streamlined assembly lowers overall costs, making space launches more economically viable.

- Scalability: The process paves the way for rapid iteration and scaling of rocket component production.

These advantages combined position Agnikul at the forefront of the evolving aerospace manufacturing landscape where agility and innovation are paramount.

US Patent: Securing Global Intellectual Property Leadership

In recognition of this technological leap, Agnikul Cosmos has been awarded a US patent for both the design and manufacturing process of its single-piece rocket engine. This intellectual property milestone grants the startup exclusive legal rights within one of the most competitive aerospace markets worldwide.

The significance of this achievement extends beyond corporate success; it reflects India’s burgeoning capability in space technology innovation and asserts its place in the global space economy. Securing a US patent also represents a formidable barrier against replication by competitors and fortifies Agnikul’s strategic leverage in international collaborations and markets.

Collaboration and Ecosystem Support Fueling Success

Agnikul’s progress underscores the power of synergistic partnerships within India’s space ecosystem. Collaborations with national agencies such as INSPACe and technological support from industry leaders like Wipro 3D have been vital. Additionally, government bodies like the Department of Science and Technology (DST) and the Technology Development Board (TDB) play a crucial role in nurturing innovation through sustained funding and facilitation.

This integrated ecosystem approach exemplifies how public-private partnerships can accelerate India’s emergence as a key player in advanced rocket propulsion and space exploration technologies.

Expert Perspective: What This Means for the Future of Space Technology

Industry analysts highlight that Agnikul’s breakthrough is more than an engineering feat — it’s a signal of shifting paradigms in aerospace production. As 3D printing matures, we can expect:

- Democratization of Space Access: Lower costs and faster production enable more startups and nations to enter the space arena.

- Customization and Rapid Innovation: Flexible manufacturing drives tailored engine designs and accelerated testing.

- Enhanced Reliability: Minimizing assembly points reduces mechanical failures, enhancing mission success rates.

For the US market and global space stakeholders, Agnikul’s patent and innovation underscore the increasing importance of safeguarding intellectual property amid intensifying competition between nations and private entities.

Challenges and Next Steps

While the achievement is remarkable, Agnikul faces challenges like scaling production for commercial launches, navigating regulatory frameworks, and constant innovation to keep pace with international rivals. Yet, with robust government and private sector backing, the startup is poised to transform India’s role from a service-heavy space participant to a technology innovator and hardware leader.

Editor’s Note

This landmark 3D-printed rocket engine by Agnikul Cosmos is a shining testament to India’s growing innovation power in space technology. It challenges the traditional manufacturing constraints and exemplifies how cutting-edge additive manufacturing can redefine aerospace engineering globally. As the space economy accelerates, the question remains: how will emerging markets like India continue to disrupt established norms and contribute uniquely to humanity’s exploration of the final frontier?

Stay tuned as Agnikul and other startups push boundaries, catalyzing a new era of faster, safer, and more accessible space travel.