Ex-Boeing Manager Highlights Manufacturing Flaws After Air India Crash

The recent crash of an Air India Boeing 787-8 Dreamliner shortly after takeoff in Ahmedabad has drawn renewed attention to longstanding concerns about Boeing’s manufacturing quality. The ill-fated flight AI-171 lost thrust and crashed into a residential area just 36 seconds after takeoff, tragically claiming hundreds of lives.

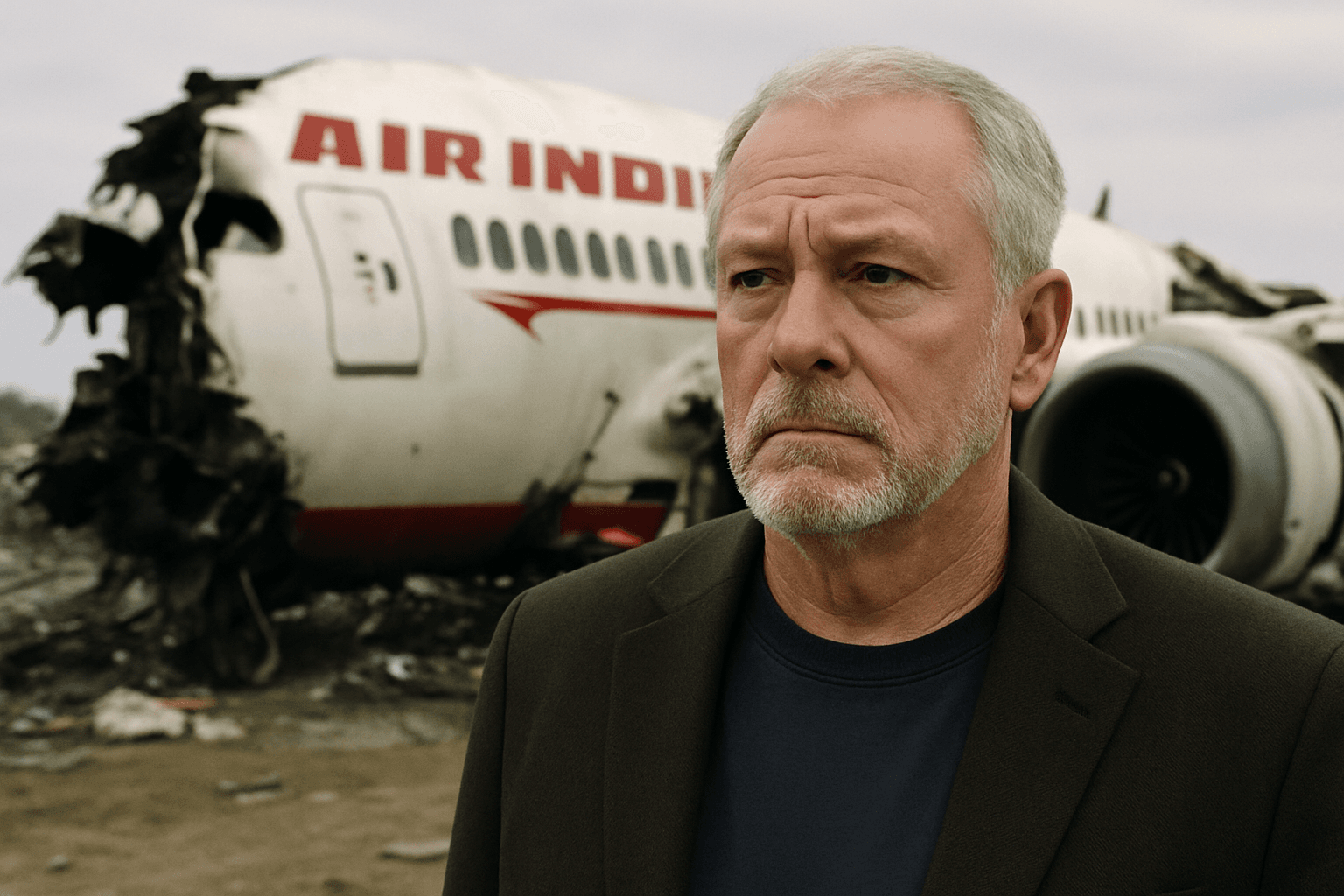

Whistleblower Exposes “Chaotic and Dangerous” Manufacturing Practices

Ed Pierson, a former senior Boeing manager turned whistleblower, spoke out about safety lapses within the company’s production lines. Having previously testified before the U.S. Congress regarding defects in Boeing’s 737 Max models, Pierson described the manufacturing process as “chaotic and dangerous.” According to him, workers have faced intense pressure to meet production targets, often resorting to makeshift methods to fit parts together—a practice flagged as unsafe.

Pierson also referenced another whistleblower, Sam Salehpour, a Boeing engineer with nearly 20 years of experience, who reported structural defects in the Dreamliner's fuselage. Salehpour highlighted issues such as improper assembly and gaps that could compromise the aircraft’s integrity, describing employees forcing parts into place in violation of standard procedures.

Manufacturing Defects Under Scrutiny After Deadly Crash

This crash marks the first involving a Boeing 787 since its 2009 introduction, spotlighting potential vulnerabilities despite rigorous safety testing the manufacturer claims to have conducted. Boeing has consistently refuted whistleblower allegations, emphasizing that the Dreamliner underwent more than 150,000 safety tests and inspections.

Following Salehpour’s warnings, the Federal Aviation Administration (FAA) launched an investigation but has so far cleared the fleet of operational 787 models. U.S. officials have stated there is no current data warranting grounding the 787 planes, although investigations into the Air India incident remain ongoing.

Is There a Link Between Manufacturing Issues and the Crash?

Regarding whether the manufacturing flaws flagged by Salehpour might have contributed to the crash, Ed Pierson did not dismiss the possibility. He noted that the troubling assembly practices reportedly persisted over a long period, suggesting the faults might have been present in the aircraft involved in the crash.

On his own whistleblowing experience related to the 737 Max, Pierson cited systemic problems including rushed production schedules, excessive employee overtime, and faults in functional and electrical system testing—highlighting a culture more focused on deadlines than on safety.

Current Investigation and Impact

Indian authorities continue their inquiry into the crash of flight AI-171, analysing voice and system data recordings from the flight. The government has set up a high-level committee to review the circumstances surrounding the accident and recommend measures to bolster aviation safety.

Reports confirm that the aircraft sent a distress signal moments after liftoff but ceased communications soon after. The crash resulted in the deaths of 242 people onboard and at least 31 fatalities on the ground, devastating the local community near Ahmedabad airport.

The tragedy underscores the critical importance of uncompromising manufacturing standards and thorough safety protocols in the aviation industry, raising pressing questions about oversight and accountability in aircraft production.