Trump’s Aluminum Tariffs: An Unexpected Catalyst for U.S. Recycling Growth

When President Donald Trump imposed sweeping tariffs of up to 50% on imported aluminum, his administration’s aim was clear: revive American aluminum smelting and manufacturing. Yet, in a twist that few anticipated, this protectionist trade policy is unintentionally fueling a greener, more economically viable recycling boom in the United States.

The Environmental and Economic Upside of Aluminum Recycling

Recycling aluminum uses a mere 5% of the energy required to produce the same amount of primary aluminum from ore, according to the International Aluminium Institute. This dramatic energy savings means recycling substantially lowers greenhouse gas emissions and environmental impacts. Against a backdrop of global climate challenges and rising energy costs, this efficiency is hard to ignore.

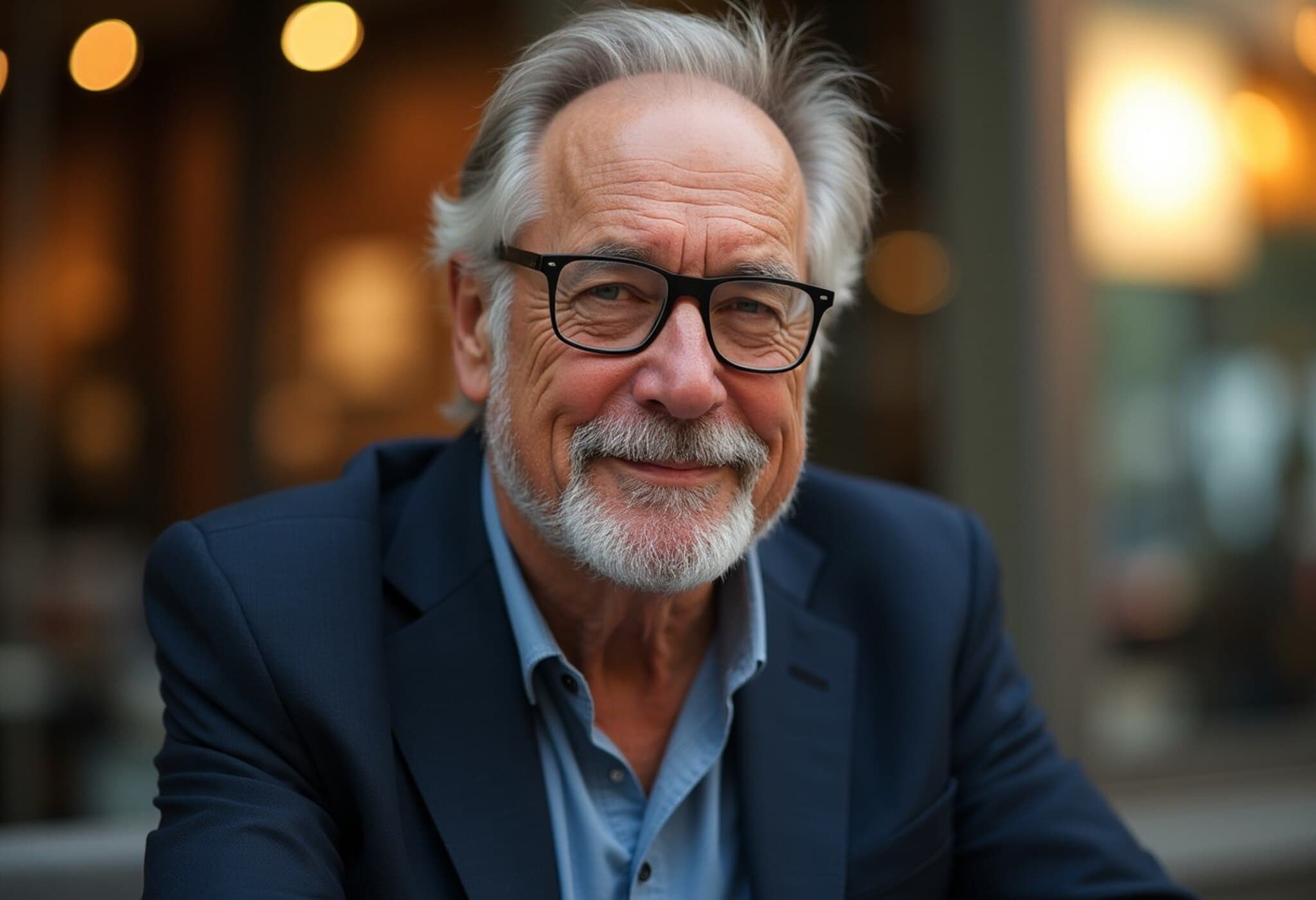

Trond Olaf Christophersen, CFO at Hydro—one of the world’s leading aluminum producers—underscores this point: “If the U.S. wants to strengthen its self-reliance on aluminum, the quickest path is to retain scrap metal domestically and bolster recycling capacity.”

Tariffs Reshape U.S. Aluminum Supply and Pricing

The United States currently faces a significant aluminum deficit, importing around 5.5 million tonnes annually to meet domestic demand, per the U.S. Department of Commerce. The new tariffs have sent import prices soaring, reflected by a sharp spike in the U.S. Midwest premium—a key pricing benchmark.

While higher prices benefit domestic smelters, they cascade through the supply chain, increasing costs for manufacturers reliant on aluminum inputs. Giants like PepsiCo and Campbell Soup have reported rising expenses on everything from beverage cans to tinplate steel packaging, prompting some to explore alternatives or seek cost reductions.

This price pressure could fuel a gradual shift away from imported primary aluminum, nudging manufacturers and suppliers to rethink sourcing toward more affordable, sustainable recycled metal.

The (Unintended) Advantage of Scrap Aluminum

Interestingly, scrap aluminum is exempt from the 50% tariff that applies to primary aluminum. This gap has created a powerful economic incentive to process scrap domestically. Recycling plants can now sell recycled aluminum into tariff-inflated markets at competitive prices, renewing demand for scrap metal and reducing exports.

Historically, the U.S. exported approximately 2 million tonnes of scrap metal every year. But recent trends show less scrap leaving American shores—partially due to tighter supplies and a growing appetite for local recycling as tariffs reshape market economics.

"Europe could become a key scrap supplier to the U.S.," Christophersen notes, though transatlantic trade uncertainties and tariff negotiations add volatility to these flows. The trajectory depends heavily on evolving U.S.-Europe trade policies.

Unlocking Recycling’s Full Potential in the U.S.

Hydro estimates that recycling all available scrap domestically is equivalent to constructing four new primary aluminum smelters. This scale could help meet roughly half of America’s current aluminum import needs, a huge step toward industrial self-sufficiency.

Policy choices such as imposing export bans or tariffs on scrap metal could further anchor raw materials in the U.S., accelerating the recycling industry’s growth.

Why Recycling Makes Business Sense Beyond Green Benefits

- Lower Capital Costs: Recycling facilities require roughly 10% of the investment needed for new primary smelters.

- Faster Build Time: Recycling plants can be operational within 1-2 years, compared to 5-6 years for smelters.

- Energy Efficiency: Lower energy needs become increasingly critical as U.S. industries compete for electricity amid surging demand, including the tech sector’s growth like AI data centers.

- Growing Market Demand: Major automotive brands such as BMW and Hyundai are actively seeking low-carbon aluminum, positioning recycled aluminum as a strategic material for sustainable manufacturing.

Bank of America analysts Michael Widmer and Francisco Blanch highlight this emerging market, suggesting U.S. recycling capacity expansion aligns with both environmental and commercial priorities.

Expert Perspective: Navigating Short-Term Costs for Long-Term Gains

While tariffs have unquestionably introduced short-term disruption and threatened billions in investments, the unintended silver lining is clear: a greener, more resilient aluminum industry rooted in recycling. Christophersen summarizes the evolving landscape succinctly, "Given the U.S. strategy to bolster material self-reliance, recycling scrap domestically represents the quickest, most effective pathway forward."

Unanswered Questions & Next Steps

- Can the U.S. government provide targeted incentives or policy measures to further internalize scrap aluminum supplies?

- How will international trade tensions, especially with Europe, influence these recycling-driven shifts?

- Will downstream manufacturers trust recycled aluminum at scale to meet strict quality and sustainability standards?

- Can this green recycling boom help the U.S. meet broader climate goals while fostering industrial competitiveness?

Editor’s Note

This evolving story reveals how trade policy, often criticized for its bluntness and unintended consequences, can sometimes catalyze unexpected environmental benefits and industrial innovations. The aluminum tariff saga is a compelling case of market forces aligning economic incentives with sustainability goals. For policymakers and business leaders alike, it underscores the importance of adopting holistic approaches that balance protectionism, climate commitments, and industry modernization.