On's LightSpray Technology: Reinventing Running Shoes

Imagine slipping into a pair of shoes that feel molded perfectly to your feet, crafted not by hand but by cutting-edge robots spraying synthetic material layer by layer. This is the breakthrough Swiss footwear brand On is pioneering with its innovative LightSpray manufacturing process—a radical departure from traditional shoe-making.

From Hundreds of Hands to Robotic Precision

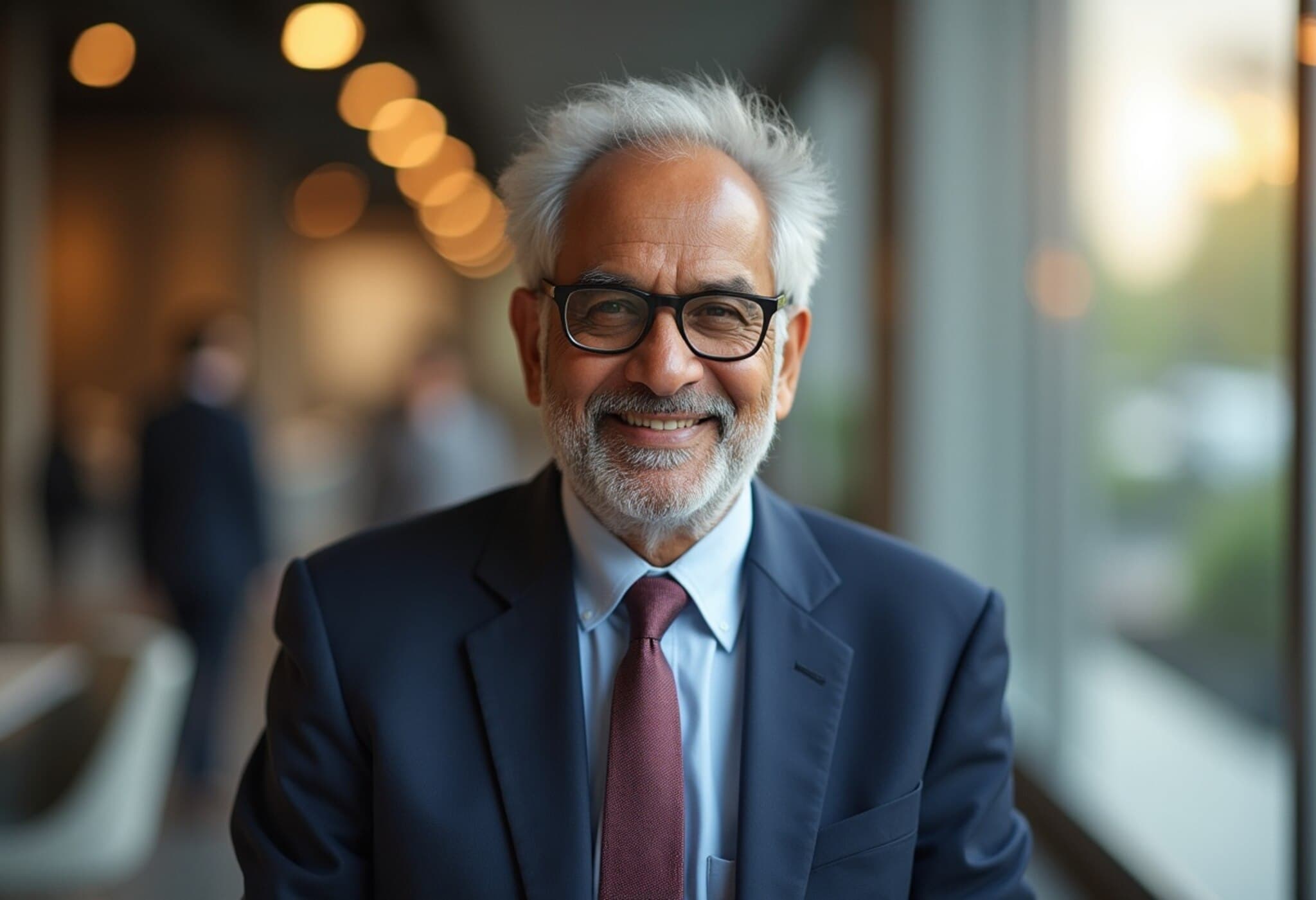

Marc Maurer, On’s former co-CEO, recently shared insights into how LightSpray dramatically streamlines production. "Usually, a traditional running shoe passes through the hands of some 200 workers," Maurer explained. "With LightSpray, the upper portion of the shoe is created automatically by a robot spraying a polymer material onto a rotating foot-shaped mold." This transformation not only reduces labor but also accelerates the manufacturing pace, taking roughly three minutes per shoe.

What Sets LightSpray Shoes Apart?

- Seamless Design: The shoes lack seams and laces, offering a sock-like fit that contours naturally to the wearer's foot.

- Durability and Comfort: The sprayed polymer creates a lightweight and flexible upper, enhancing long-distance running comfort.

- Sustainability Potential: Automated spraying could reduce material waste compared to cut-and-sew processes.

Scaling Innovation: From Thousands to Millions

Though still in its early stages, On aims to scale LightSpray production massively. The brand recently announced the opening of its first dedicated LightSpray factory in Zurich, equipped with four robotic sprayers. Maurer is optimistic about the future: "Our goal is to evolve from producing just a few thousand pairs to manufacturing millions." This scale-up could reshape the sportswear industry, offering consumers high-tech, custom-feeling shoes produced with minimal environmental impact.

Contextualizing the Impact

The LightSpray technique exemplifies a broader trend in manufacturing: increased automation combined with customization. In the highly competitive athletic footwear market, this could position On as a technology leader, potentially disrupting giants reliant on conventional assembly lines. Moreover, from an American market perspective, innovations like these raise questions about future labor dynamics, supply chain localization, and sustainability standards in the footwear sector.

Critical Perspectives and Questions

- How will LightSpray influence labor markets in traditional shoe manufacturing hubs?

- What are the environmental trade-offs involved in polymer spraying compared to traditional materials?

- Can this technology enable more personalized, on-demand production aligning with consumer demands?

Editor’s Note

On's LightSpray innovation opens a fascinating window into the future of footwear production—where robotics meet artisanal fit. As automation advances, how brands balance efficiency, quality, and sustainability will shape the industry for decades. Readers should watch closely how this technology grows, not just for its novelty, but for its potential to redefine manufacturing norms and consumer expectations alike.